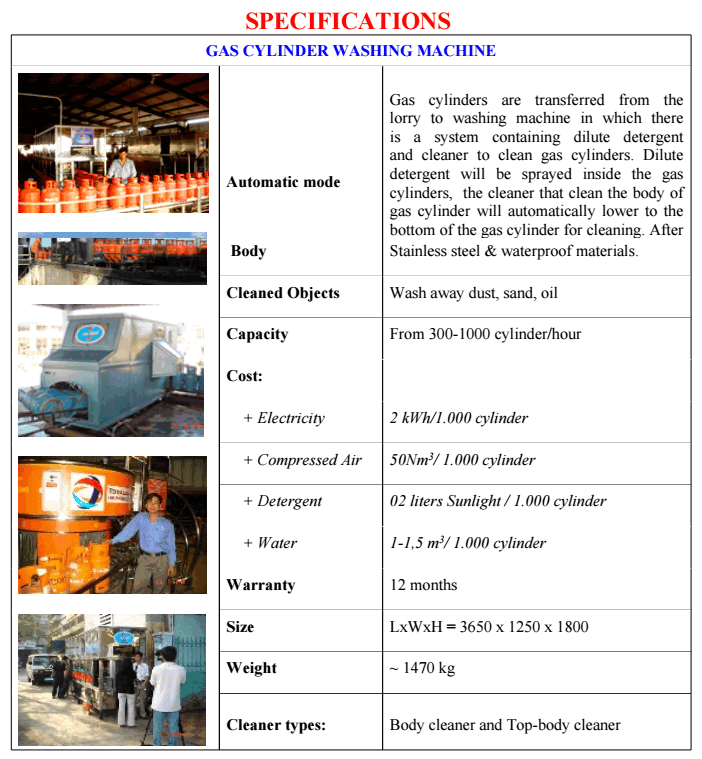

GAS CYLINDER WASHING MACHINE

SIGNAFICIANT FUNCTION – RESONABLE PRICE

Making high-tech branch name for your gas charging business.

Compact, efficience, and easy to operate.

Save Manpower, Automatico production, Reduce cost.

Durable machines, Spare parts available.

Keep your prestige and branch name in the market.

Gas cylinder washing machine is manufactured based on

Patent #5411 issued by Minister of Science and

Technology of Vietnam on Jan. 10th 2006

This product has been used by TOTAL GAS VIETNAM (3 machines),

TOTAL GAS HAI PHONG, TOTAL GAS INDIA, SCT GAS THAILAND,

FAMILY GAS, HOANG AN GAS, SAIGON PETRO (4 machines),

PETROVIETNAM

| Title:Design, Manufacture Gas cylinder washing machine runned compressed air |

| Code: 3/2006 |

| Author: Engineer PHAN DINH PHUONG |

| Lead agency: An Sinh Technology Inventory Co., |

| Time: Sep. 2005- Feb. 2006 |

| Goals:

- Deploy compressed air technology, manufacture Vietnam gas holder washing machine with light, compact, and auto-operated features to clean the outside of the gas holder body or similar objects for the purpose of insuring commercial culture, reducing pollution, protecting labor health. - Eliminate flammable capability due to electric shock in gas warehouse. - Washing performance: 400 bottles/hour. - Consumption: 2-4kg detergent/1000 bottles, water: 1.5l/bottle, compressed air: 80 m3/h.

- Semi auto-operated machine by using compressed air.

|

| Content:

Producing a gas-bottle washing method by using pure compressed air and continuous equipment system, which is quite handy and able to automate the entire process, wash a lot of bottles having different hands on product loading line. However, bottle washing machine for gas loading line should guarantee safety strictly. It would not use the power directly but compressed air to motivate all engines and automatic control systems; machine building materials should be water-resistant and don’t release ignition when contracting holders during cleaning process. The systems do not mess up loading chain and lubricants on that chain. The cost of compressed air soaps, lubricants consumption, etc. and machine prices must be the lowest to lower product price. |

| Product:

Product with following specifications:

- Machine just use compressed air, not use electricity, it is safe.

- Machine has broom whole body, top, bottom of bottle, helps gas cylinder

clean every corner.

- Cylinder run through machine automatically without chain, which dismisses

electricity fee in this term.

- Machine can wash available tools.

- Machine can work replacing for 4 workers who work by hand.

- Cost:

+ Water: 1,5 litre/gas cylinder.

+ Sunlight detergent: 2-4 litre/1000 gas cylinders.

+ Compressed air consumption: 4kg/cm2.

+ Oil consumption: SAE20 is 7000 gas cylinders/litre (20-30 times lower than

imported ones).

- Washing performance: wash away sand, oil, chemical glue, ink… It cleans

|

| Result:

- We made research to manufacture a gas cylinder washing machine run by

compressed air with following specifications:

+ Run by compressed air, not chain.

+ Washing performance: max 600 gas cylinders/hour.

+ Detergent consumption: 2-4kg Sunlight/1000 gas cylinders.

+ Water consumption: 1,5 litre/gas cylinder.

+ Conpressed consumption: 80 m3/hour.

+ Automatic level: semi-automatic, only need one worker.

+ Safety: Don’t use electricity, so, it is safe.

- Gas cylinder washing machine run by compressed air, no chain, with

specifications which satisfies customers’demands, clean bottle up to 90 95%. An Sinh

washing machine is made to replace for the foreign worth 47000 USD (include: body

35.000 USD, chain 12.000 USD). It is safe thanks to no use electricity in gas

warehouse. |